Course Outline –

Design of Experiment Workshop (2 days)

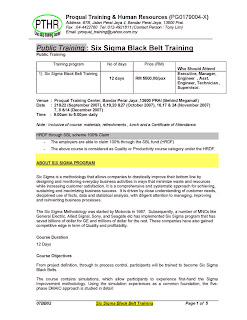

Venue : Pearl View Hotel , Prai

Design of Experiment Workshop (2 days)

Venue : Pearl View Hotel , Prai

Date : 9 & 10 Oct 2007

Time : 9am~5pm

Fee : RM500 per person. (* special discount for group registration)

INTRODUCTION

DOE is now recognized as a key strategic element to help organizations remain competitive and profitable in today's business climate which demands consistency and quality.

A Design of Experiment (DOE) is a structured, organized method for determining the relationship between factors affecting a process and the output of that process.

It is a systematic methodology that dramatically improves industrial products and processes thus enhancing productivity and reducing costs. Input factors are varied in a planned manner to efficiently optimize output responses of interest with minimal variability.

This training provides a comprehensive exposure to the use of powerful DOE techniques for improving and optimizing any process. During this workshop, you will learn how to set up and run basic factorial and screening experiments; how to analyze experimental outcomes; identify significant effects on process performance and consistency; and identify factors for further study or implementation. Then, in a workshop environment you will design and conduct experiments.

Duration

2 days (9am-5pm)

OBJECTIVES

After the training, the participants will be able to:

· understand the advantages of using experimental design over trial and error methods

· set up and run basic factorial and screening experiments

· analyze experimental outcomes

· identify significant effects on process performance and consistency

· identify factors for further study

· optimize the output performance of a process or product

· use relevant techniques & tools for DOE implementation.

· correct the mistakes or overcome the problems encountered during DOE implementation.

WHO SHOULD ATTEND

This course is designed for those managers, engineers, & professionals who

intend to apply DOE for process optimization.

responsible for developing or improving products and processes.

No previous exposure to designed experiments is required.

COURSE CONTENT

Day 1 – 9.00 am – 5.00 pm

Module 1 : Introduction to DOE

· What is DOE?

· Why do a designed experiment?

· Try and error method and OFAT (One-Factor-At-A-Time)

· Types of experiment

· Steps for implementing DOE

· Practical examples

Module 2 : DOE Terminology

· Statistical assumptions for DOE

· Understanding on process variation & p value

· Sampling strategies

· Randomization

· Blocking

· Main Effects and Interactions

· Coded setting

· Un-coding the setting

· Introduction to ANOVA

Module 3 : Two factors factorial design

· Why do we need to use 2k factorial experimentation?

· 2k Vocabulary

· Steps for DOE Analysis

· 2k Standard Order Designs

· Calculating main effects

· Calculating interactions

· Adding Center Points

· Adding Blocking

· 2k Example and Exercise

· Interpretation of results and necessary actions

Day 2 (9.00am- 5.00pm)

Section 4 : Three-Factor Full -Factorial Design

· Graphical Interpretation of Effects and Interactions

· Statistical Concepts

· Determining Statistical Significance

· Interpretation of results and necessary actions

· Design and Analysis

· Practical workshop

Module 5 : Fractional Factorial Design

· Fractional Factorials

· Defining Relation

· Confounding

· Resolution

· Factor Assignment

· Interpretation of results and necessary actions

· Practical workshop

Module 6 : Introduction To Advanced DOE

· Advanced DOE

· Response Surface Methodology (RSM)

· Multiple Responses Optimization

· Taguchi method

Trainer profile:

1. Mr. Tony Lim

Tony Lim, Master of Science (USM, Penang)

Tony Lim is a certified quality auditor and is a Training Specialist by profession.

He is a multilingual facilitator with more than 5 years of consulting and training

experience in ISO 9000 quality management, six sigma deployment, statistical

process control and lean manufacturing. He has more than 15 years of

experience in quality system management, 5 of them as a quality manager for

one of leading MNC.

He has often been invited to conduct training for various manufacturing

companies in Asia Pacific Region.

His main accomplishments were setting up and implementing the ISO 9000

Quality Management System and Six Sigma Deployments for various

manufacturing companies.

2) Mr Roshidi Mat Rejab

Roshidi, Master of Mechanical Engineering (Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of operation team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Lean manufacturing, overall equipment effectiveness, DOE, FMEA, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).

INTRODUCTION

DOE is now recognized as a key strategic element to help organizations remain competitive and profitable in today's business climate which demands consistency and quality.

A Design of Experiment (DOE) is a structured, organized method for determining the relationship between factors affecting a process and the output of that process.

It is a systematic methodology that dramatically improves industrial products and processes thus enhancing productivity and reducing costs. Input factors are varied in a planned manner to efficiently optimize output responses of interest with minimal variability.

This training provides a comprehensive exposure to the use of powerful DOE techniques for improving and optimizing any process. During this workshop, you will learn how to set up and run basic factorial and screening experiments; how to analyze experimental outcomes; identify significant effects on process performance and consistency; and identify factors for further study or implementation. Then, in a workshop environment you will design and conduct experiments.

Duration

2 days (9am-5pm)

OBJECTIVES

After the training, the participants will be able to:

· understand the advantages of using experimental design over trial and error methods

· set up and run basic factorial and screening experiments

· analyze experimental outcomes

· identify significant effects on process performance and consistency

· identify factors for further study

· optimize the output performance of a process or product

· use relevant techniques & tools for DOE implementation.

· correct the mistakes or overcome the problems encountered during DOE implementation.

WHO SHOULD ATTEND

This course is designed for those managers, engineers, & professionals who

intend to apply DOE for process optimization.

responsible for developing or improving products and processes.

No previous exposure to designed experiments is required.

COURSE CONTENT

Day 1 – 9.00 am – 5.00 pm

Module 1 : Introduction to DOE

· What is DOE?

· Why do a designed experiment?

· Try and error method and OFAT (One-Factor-At-A-Time)

· Types of experiment

· Steps for implementing DOE

· Practical examples

Module 2 : DOE Terminology

· Statistical assumptions for DOE

· Understanding on process variation & p value

· Sampling strategies

· Randomization

· Blocking

· Main Effects and Interactions

· Coded setting

· Un-coding the setting

· Introduction to ANOVA

Module 3 : Two factors factorial design

· Why do we need to use 2k factorial experimentation?

· 2k Vocabulary

· Steps for DOE Analysis

· 2k Standard Order Designs

· Calculating main effects

· Calculating interactions

· Adding Center Points

· Adding Blocking

· 2k Example and Exercise

· Interpretation of results and necessary actions

Day 2 (9.00am- 5.00pm)

Section 4 : Three-Factor Full -Factorial Design

· Graphical Interpretation of Effects and Interactions

· Statistical Concepts

· Determining Statistical Significance

· Interpretation of results and necessary actions

· Design and Analysis

· Practical workshop

Module 5 : Fractional Factorial Design

· Fractional Factorials

· Defining Relation

· Confounding

· Resolution

· Factor Assignment

· Interpretation of results and necessary actions

· Practical workshop

Module 6 : Introduction To Advanced DOE

· Advanced DOE

· Response Surface Methodology (RSM)

· Multiple Responses Optimization

· Taguchi method

Trainer profile:

1. Mr. Tony Lim

Tony Lim, Master of Science (USM, Penang)

Tony Lim is a certified quality auditor and is a Training Specialist by profession.

He is a multilingual facilitator with more than 5 years of consulting and training

experience in ISO 9000 quality management, six sigma deployment, statistical

process control and lean manufacturing. He has more than 15 years of

experience in quality system management, 5 of them as a quality manager for

one of leading MNC.

He has often been invited to conduct training for various manufacturing

companies in Asia Pacific Region.

His main accomplishments were setting up and implementing the ISO 9000

Quality Management System and Six Sigma Deployments for various

manufacturing companies.

2) Mr Roshidi Mat Rejab

Roshidi, Master of Mechanical Engineering (Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of operation team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Lean manufacturing, overall equipment effectiveness, DOE, FMEA, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).