Thursday, September 27, 2007

Monday, September 24, 2007

Tuesday, September 18, 2007

廢物減少是精瘦的製造業的目標

精瘦的製造業準具體區域為廢減少。

什麼是需要? 什麼是廢物? 顧客要求的不是廢物。

引導精瘦的製造過程的五項原則:

1)定義"價值" : 顧客真正地想要什麼?

2)創造連續的產品流程。

3)使非價值增加的活動減到最少: 這些包括WIP。

4)讓顧客拉扯(Pull) 產品。

5)連續追求改善: 問一切, 和總要求"為什麼?"

TONY LIM 19-Sep-2007 Malaysia

tonycclim@yahoo.com

(+6012-4921811)

什麼是需要? 什麼是廢物? 顧客要求的不是廢物。

引導精瘦的製造過程的五項原則:

1)定義"價值" : 顧客真正地想要什麼?

2)創造連續的產品流程。

3)使非價值增加的活動減到最少: 這些包括WIP。

4)讓顧客拉扯(Pull) 產品。

5)連續追求改善: 問一切, 和總要求"為什麼?"

TONY LIM 19-Sep-2007 Malaysia

tonycclim@yahoo.com

(+6012-4921811)

什麼是精瘦的製造業系統? Lean Manufacturing

生產要求三個基本的元素: 人、機器, 和材料。(Man, Machine & Material)

精瘦的生產是有效地運用這些三個基本的元素, 減少廢和增長的生產力當改進質量。

實施精瘦的生產是一個長的過程,要求變革包含您的整個企業, 從原材料購買。

在您精瘦的變革旅途期間它是共同體會以下整體表現改善: Result

-行政週期 減少50-90%

-瑕疵 減少50% 每年, 以無次品表現可能

-新產品開發時間 減少75%

-資本化 成本降低50%

-交付前置時間 減少超過75%

-準時交付 改善99+%

-雇員態度 調查結果顯著被改進

-生產力 (銷售每雇員)每年增量15-35%

-存貨 (週轉資本) 減少超過75%

精瘦的生產是有效地運用這些三個基本的元素, 減少廢和增長的生產力當改進質量。

實施精瘦的生產是一個長的過程,要求變革包含您的整個企業, 從原材料購買。

在您精瘦的變革旅途期間它是共同體會以下整體表現改善: Result

-行政週期 減少50-90%

-瑕疵 減少50% 每年, 以無次品表現可能

-新產品開發時間 減少75%

-資本化 成本降低50%

-交付前置時間 減少超過75%

-準時交付 改善99+%

-雇員態度 調查結果顯著被改進

-生產力 (銷售每雇員)每年增量15-35%

-存貨 (週轉資本) 減少超過75%

Thursday, September 6, 2007

How do you change strategies?

1.) Understand your current strategy, then try to figure out a proactive long-term strategy.

2.) Try to figure out what it is you’re trying to do, accomplish, build and sustain with your business.

3.) Determine what is operating approach that will get you the greatest result you want in the fastest period of time on the most sustaining and enduring basis.

4.) Generate a list of the highest performing, most impressive, sustaining, successful and formidable companies you know of, inside or outside your industry.

5.)Take time to think about what their "big business" strategy really is. What is it they’re trying to do with all the tactics they mount.

6.)Take time to think through how they are doing it or accomplishing it. That’ll break out for you the difference between strategy and tactics. If you’ve done this exercise for one hundred companies, then ask at least a dozen of your friends to do it for you for ten or fifteen companies that theyknow.

7.)Then you can break down a combination of a couple of hundred strategies that you’ve identified and you can evaluate which ones (or composite ones) you can borrow, then combine together to forge your own ultimate replacement business strategy.

2.) Try to figure out what it is you’re trying to do, accomplish, build and sustain with your business.

3.) Determine what is operating approach that will get you the greatest result you want in the fastest period of time on the most sustaining and enduring basis.

4.) Generate a list of the highest performing, most impressive, sustaining, successful and formidable companies you know of, inside or outside your industry.

5.)Take time to think about what their "big business" strategy really is. What is it they’re trying to do with all the tactics they mount.

6.)Take time to think through how they are doing it or accomplishing it. That’ll break out for you the difference between strategy and tactics. If you’ve done this exercise for one hundred companies, then ask at least a dozen of your friends to do it for you for ten or fifteen companies that theyknow.

7.)Then you can break down a combination of a couple of hundred strategies that you’ve identified and you can evaluate which ones (or composite ones) you can borrow, then combine together to forge your own ultimate replacement business strategy.

Do you train your people?

Every dollar you spend in training will produce at least 20 times return annually

in yield.

Do you train your people?

How often or frequently?

Do you train your selling people in formal professional consultative selling?

Do you train your office staff in all the skill sets needed to perform at superstar levels?

Are they the most effective in efficiency or productivity?

If you can get each of your people 10% better in each of those categories, you’ve just doubled or tripled the effectiveness.

Or you’ll be able to achieve the same result from one half the staff, time or 75% cost.

in yield.

Do you train your people?

How often or frequently?

Do you train your selling people in formal professional consultative selling?

Do you train your office staff in all the skill sets needed to perform at superstar levels?

Are they the most effective in efficiency or productivity?

If you can get each of your people 10% better in each of those categories, you’ve just doubled or tripled the effectiveness.

Or you’ll be able to achieve the same result from one half the staff, time or 75% cost.

Wednesday, September 5, 2007

Reaction to an Out-of-Control Signal (Control Chart)

Reaction to an Out-of-Control Signal

•It is very important to investigate every signal of special-cause variation

–Without attention to the charts, those responsible will begin ignoring the signals

•Necessary to have a planned approach

–Verify that data is correct and has been entered correctly

–Determine if a simple explanation of special cause is available (e.g. parts were dropped)

–Verify process change by taking a bigger sample (>20). Use proper sample size to detect critical difference.

–If process change is real, assess process impact to determine next courses of action:

•Line shut down

•Root cause investigation

Out of control signals:

1)Main Indicators

•any point outside of a control limit

•any point outside of a control limit

2)Secondary Indicators

•any non-random pattern of points on a control chart

–shift or run

–trend

–stratification

–mixture

–periodicity

•any non-random pattern of points on a control chart

–shift or run

–trend

–stratification

–mixture

–periodicity

Tuesday, September 4, 2007

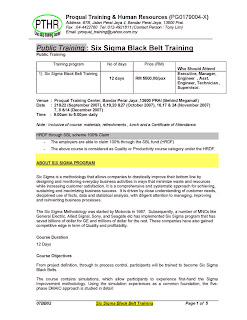

DOE Workshop (2 days) 9&10 Oct, Pearl View Hotel, Prai

Course Outline –

Design of Experiment Workshop (2 days)

Venue : Pearl View Hotel , Prai

Design of Experiment Workshop (2 days)

Venue : Pearl View Hotel , Prai

Date : 9 & 10 Oct 2007

Time : 9am~5pm

Fee : RM500 per person. (* special discount for group registration)

INTRODUCTION

DOE is now recognized as a key strategic element to help organizations remain competitive and profitable in today's business climate which demands consistency and quality.

A Design of Experiment (DOE) is a structured, organized method for determining the relationship between factors affecting a process and the output of that process.

It is a systematic methodology that dramatically improves industrial products and processes thus enhancing productivity and reducing costs. Input factors are varied in a planned manner to efficiently optimize output responses of interest with minimal variability.

This training provides a comprehensive exposure to the use of powerful DOE techniques for improving and optimizing any process. During this workshop, you will learn how to set up and run basic factorial and screening experiments; how to analyze experimental outcomes; identify significant effects on process performance and consistency; and identify factors for further study or implementation. Then, in a workshop environment you will design and conduct experiments.

Duration

2 days (9am-5pm)

OBJECTIVES

After the training, the participants will be able to:

· understand the advantages of using experimental design over trial and error methods

· set up and run basic factorial and screening experiments

· analyze experimental outcomes

· identify significant effects on process performance and consistency

· identify factors for further study

· optimize the output performance of a process or product

· use relevant techniques & tools for DOE implementation.

· correct the mistakes or overcome the problems encountered during DOE implementation.

WHO SHOULD ATTEND

This course is designed for those managers, engineers, & professionals who

intend to apply DOE for process optimization.

responsible for developing or improving products and processes.

No previous exposure to designed experiments is required.

COURSE CONTENT

Day 1 – 9.00 am – 5.00 pm

Module 1 : Introduction to DOE

· What is DOE?

· Why do a designed experiment?

· Try and error method and OFAT (One-Factor-At-A-Time)

· Types of experiment

· Steps for implementing DOE

· Practical examples

Module 2 : DOE Terminology

· Statistical assumptions for DOE

· Understanding on process variation & p value

· Sampling strategies

· Randomization

· Blocking

· Main Effects and Interactions

· Coded setting

· Un-coding the setting

· Introduction to ANOVA

Module 3 : Two factors factorial design

· Why do we need to use 2k factorial experimentation?

· 2k Vocabulary

· Steps for DOE Analysis

· 2k Standard Order Designs

· Calculating main effects

· Calculating interactions

· Adding Center Points

· Adding Blocking

· 2k Example and Exercise

· Interpretation of results and necessary actions

Day 2 (9.00am- 5.00pm)

Section 4 : Three-Factor Full -Factorial Design

· Graphical Interpretation of Effects and Interactions

· Statistical Concepts

· Determining Statistical Significance

· Interpretation of results and necessary actions

· Design and Analysis

· Practical workshop

Module 5 : Fractional Factorial Design

· Fractional Factorials

· Defining Relation

· Confounding

· Resolution

· Factor Assignment

· Interpretation of results and necessary actions

· Practical workshop

Module 6 : Introduction To Advanced DOE

· Advanced DOE

· Response Surface Methodology (RSM)

· Multiple Responses Optimization

· Taguchi method

Trainer profile:

1. Mr. Tony Lim

Tony Lim, Master of Science (USM, Penang)

Tony Lim is a certified quality auditor and is a Training Specialist by profession.

He is a multilingual facilitator with more than 5 years of consulting and training

experience in ISO 9000 quality management, six sigma deployment, statistical

process control and lean manufacturing. He has more than 15 years of

experience in quality system management, 5 of them as a quality manager for

one of leading MNC.

He has often been invited to conduct training for various manufacturing

companies in Asia Pacific Region.

His main accomplishments were setting up and implementing the ISO 9000

Quality Management System and Six Sigma Deployments for various

manufacturing companies.

2) Mr Roshidi Mat Rejab

Roshidi, Master of Mechanical Engineering (Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of operation team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Lean manufacturing, overall equipment effectiveness, DOE, FMEA, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).

INTRODUCTION

DOE is now recognized as a key strategic element to help organizations remain competitive and profitable in today's business climate which demands consistency and quality.

A Design of Experiment (DOE) is a structured, organized method for determining the relationship between factors affecting a process and the output of that process.

It is a systematic methodology that dramatically improves industrial products and processes thus enhancing productivity and reducing costs. Input factors are varied in a planned manner to efficiently optimize output responses of interest with minimal variability.

This training provides a comprehensive exposure to the use of powerful DOE techniques for improving and optimizing any process. During this workshop, you will learn how to set up and run basic factorial and screening experiments; how to analyze experimental outcomes; identify significant effects on process performance and consistency; and identify factors for further study or implementation. Then, in a workshop environment you will design and conduct experiments.

Duration

2 days (9am-5pm)

OBJECTIVES

After the training, the participants will be able to:

· understand the advantages of using experimental design over trial and error methods

· set up and run basic factorial and screening experiments

· analyze experimental outcomes

· identify significant effects on process performance and consistency

· identify factors for further study

· optimize the output performance of a process or product

· use relevant techniques & tools for DOE implementation.

· correct the mistakes or overcome the problems encountered during DOE implementation.

WHO SHOULD ATTEND

This course is designed for those managers, engineers, & professionals who

intend to apply DOE for process optimization.

responsible for developing or improving products and processes.

No previous exposure to designed experiments is required.

COURSE CONTENT

Day 1 – 9.00 am – 5.00 pm

Module 1 : Introduction to DOE

· What is DOE?

· Why do a designed experiment?

· Try and error method and OFAT (One-Factor-At-A-Time)

· Types of experiment

· Steps for implementing DOE

· Practical examples

Module 2 : DOE Terminology

· Statistical assumptions for DOE

· Understanding on process variation & p value

· Sampling strategies

· Randomization

· Blocking

· Main Effects and Interactions

· Coded setting

· Un-coding the setting

· Introduction to ANOVA

Module 3 : Two factors factorial design

· Why do we need to use 2k factorial experimentation?

· 2k Vocabulary

· Steps for DOE Analysis

· 2k Standard Order Designs

· Calculating main effects

· Calculating interactions

· Adding Center Points

· Adding Blocking

· 2k Example and Exercise

· Interpretation of results and necessary actions

Day 2 (9.00am- 5.00pm)

Section 4 : Three-Factor Full -Factorial Design

· Graphical Interpretation of Effects and Interactions

· Statistical Concepts

· Determining Statistical Significance

· Interpretation of results and necessary actions

· Design and Analysis

· Practical workshop

Module 5 : Fractional Factorial Design

· Fractional Factorials

· Defining Relation

· Confounding

· Resolution

· Factor Assignment

· Interpretation of results and necessary actions

· Practical workshop

Module 6 : Introduction To Advanced DOE

· Advanced DOE

· Response Surface Methodology (RSM)

· Multiple Responses Optimization

· Taguchi method

Trainer profile:

1. Mr. Tony Lim

Tony Lim, Master of Science (USM, Penang)

Tony Lim is a certified quality auditor and is a Training Specialist by profession.

He is a multilingual facilitator with more than 5 years of consulting and training

experience in ISO 9000 quality management, six sigma deployment, statistical

process control and lean manufacturing. He has more than 15 years of

experience in quality system management, 5 of them as a quality manager for

one of leading MNC.

He has often been invited to conduct training for various manufacturing

companies in Asia Pacific Region.

His main accomplishments were setting up and implementing the ISO 9000

Quality Management System and Six Sigma Deployments for various

manufacturing companies.

2) Mr Roshidi Mat Rejab

Roshidi, Master of Mechanical Engineering (Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of operation team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Lean manufacturing, overall equipment effectiveness, DOE, FMEA, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).

Wednesday, August 29, 2007

Project Management Training (2 days)

Project Management Training

Venue : Pearl View Hotel, Prai , Penang

Time : 9.00am~5.00pm

Date : 25 & 26 September 2007

Duration : 2 days

PLS CONTACT TONY 012-4921811 or email to proqual_training@yahoo.com.my for registration.

Overview – Project Management Training

In today’s fast-paced business world, organizations that practice sound project management principles secure competitive advantage over those that run the projects by experience alone. Project management is the application of knowledge, skills, tools, and techniques to a broad range of activities in order to successfully meet predetermined project requirements.

In this 2 days session, you will be introduced to the best practices of project management. With hands-on activities, you'll go from novice to expert and learn how to effectively manage all phases of a project. This course uses the structured project management framework of initiation, planning, execution, control, and formal closing, teaching you the steps that ensure project success. The course focuses on practical tools and techniques you can use immediately back on the job. Through class exercises and realistic simulations, attendees learn how the principles of project management are put into practice.

Course objectives

Upon completion of this course, the participants will be able

-Define basic terminology of project management

-Identify the project management life cycle

-Understand the project management knowledge areas

-Build a business case for project initiation

-Define project scope and stakeholder expectations

-Define roles and responsibilities for project stakeholders

-Build an effective project schedule

-Identify, analyze, quantify, mitigate, and manage risks

-Create project management plans

-Manage project change through formal change control processes

-Close a project

Who Should Attend?

Anyone seeking a structured project management method

Project managers/engineers currently experiencing difficulty keeping projects on the track.

Executives and supervisors who want a better understanding of the project management process.

Course Outline

Day 1 (9.00am-5.00pm)

1. Fundamental of Project Management

· What is a Project Management?

· Life Cycles

· Project Management Processes

· Project Management Terminology

2. Initiating

Project Scope Management

· Initiation

· Scope Planning

· Scope Definition

· Scope Verification

· Scope Change Control

Five Steps of Project Initiation

Stakeholder Analysis

Project Roles and Responsibilities

Sign-Off Process

Video examples – initiating the project successfully

3. Planning

Project Time Management

Project Cost Management

Project Quality Management

Project Human Resource Management

Project Communications Management

Project Risk Management

Project Procurement Management

Workshop

Day 2 (9.00am ~ 5.00pm)

4. Controlling and Closing

Project Controls

The Constraints Quartet

Focus on Past and Future

Project Meeting Tips

Key Principles for Control

Challenges

Activity Analysis

Expectations

Stakeholder Expectations

Project Environment

Expectation Control Elements

Project Manager vs. Expectation Gap

Organizational Style

Why do Projects Fail?

5. Closing Processes

6. Case Studies

7. Workshops

Trainer profile

Mr Roshidi Mat Rejab

Master of Mechanical Engineering

(Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of project management team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance worked as project manager at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Project Management, Lean manufacturing, overall equipment effectiveness, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).

Venue : Pearl View Hotel, Prai , Penang

Time : 9.00am~5.00pm

Date : 25 & 26 September 2007

Duration : 2 days

PLS CONTACT TONY 012-4921811 or email to proqual_training@yahoo.com.my for registration.

Overview – Project Management Training

In today’s fast-paced business world, organizations that practice sound project management principles secure competitive advantage over those that run the projects by experience alone. Project management is the application of knowledge, skills, tools, and techniques to a broad range of activities in order to successfully meet predetermined project requirements.

In this 2 days session, you will be introduced to the best practices of project management. With hands-on activities, you'll go from novice to expert and learn how to effectively manage all phases of a project. This course uses the structured project management framework of initiation, planning, execution, control, and formal closing, teaching you the steps that ensure project success. The course focuses on practical tools and techniques you can use immediately back on the job. Through class exercises and realistic simulations, attendees learn how the principles of project management are put into practice.

Course objectives

Upon completion of this course, the participants will be able

-Define basic terminology of project management

-Identify the project management life cycle

-Understand the project management knowledge areas

-Build a business case for project initiation

-Define project scope and stakeholder expectations

-Define roles and responsibilities for project stakeholders

-Build an effective project schedule

-Identify, analyze, quantify, mitigate, and manage risks

-Create project management plans

-Manage project change through formal change control processes

-Close a project

Who Should Attend?

Anyone seeking a structured project management method

Project managers/engineers currently experiencing difficulty keeping projects on the track.

Executives and supervisors who want a better understanding of the project management process.

Course Outline

Day 1 (9.00am-5.00pm)

1. Fundamental of Project Management

· What is a Project Management?

· Life Cycles

· Project Management Processes

· Project Management Terminology

2. Initiating

Project Scope Management

· Initiation

· Scope Planning

· Scope Definition

· Scope Verification

· Scope Change Control

Five Steps of Project Initiation

Stakeholder Analysis

Project Roles and Responsibilities

Sign-Off Process

Video examples – initiating the project successfully

3. Planning

Project Time Management

Project Cost Management

Project Quality Management

Project Human Resource Management

Project Communications Management

Project Risk Management

Project Procurement Management

Workshop

Day 2 (9.00am ~ 5.00pm)

4. Controlling and Closing

Project Controls

The Constraints Quartet

Focus on Past and Future

Project Meeting Tips

Key Principles for Control

Challenges

Activity Analysis

Expectations

Stakeholder Expectations

Project Environment

Expectation Control Elements

Project Manager vs. Expectation Gap

Organizational Style

Why do Projects Fail?

5. Closing Processes

6. Case Studies

7. Workshops

Trainer profile

Mr Roshidi Mat Rejab

Master of Mechanical Engineering

(Old Dominion University, Norfolk, U.S.A in 1987)

Roshidi has spent more than 16 years in world leaders manufacturing environment as key person of project management team. Besides working in major international companies in Malaysia, he has also worked abroad; for instance worked as project manager at Intel,Phoenix plant, Arizona, U.S.A.(1988~1992).

Experiences and educations gained abroad lifted up his way of thinking towards a more global manner, as demonstrated in his performance at work.

Over the past four years, he has facilitated more than 100 practical workshops in Asia Pacific region dealing with principles of Project Management, Lean manufacturing, overall equipment effectiveness, value stream mapping, visual factory, Genba Kaizen, kanban systems, setup reduction, and total productive maintenance (TPM).

Sunday, August 26, 2007

Thursday, August 23, 2007

How to redefine your company quality strategy? Part II

Wednesday, August 22, 2007

How to redefine your company quality strategy? Part I

With technology and globalization changing the business environment at whiplash inducing speeds, quality strategy redefinition is a necessity. But before you take any action, you should find out your company’s existing strengths and capabilities.

Here some of areas for your consideration:

1.1 Study your existing SPC implementation :

Here are 5 levels of SPC implementation

Level 1 - SPC as wallpaper only, without proper training

Level 2 - SPC on X’s or Y’s with fully trained operators. Operators will understand the signals, but management will not empower them to stop for investigation. Operators will learn to ignore or disconnect the warning signals once production becomes the #1 priority.

Level 3 - SPC, with Corrective Action = Inspection. Short term containment equals auditing or 100% inspection.

Level 4 - SPC, with Corrective Action = Equipment Flag. Process is stopped or equipment automatically shuts down, so that defects will not move forward.

Level 5 - SPC, with Corrective Action = Countermeasure. Improvements are made so that defect cannot occur again.

Where are you ? Are at the best (level 5) or the worst (level 1).

1.2 SPC - should apply on procuss inputs instead of outputs

Most companies apply SPC to finished goods (Y’s) rather than process characteristics (X’s).

The full power of SPC methods to improve quality, increase productivity, and reduce cost can only be realized if the process inputs become the focus of our effort.

Tony Lim 23-Aug-2007

Here some of areas for your consideration:

1.1 Study your existing SPC implementation :

Here are 5 levels of SPC implementation

Level 1 - SPC as wallpaper only, without proper training

Level 2 - SPC on X’s or Y’s with fully trained operators. Operators will understand the signals, but management will not empower them to stop for investigation. Operators will learn to ignore or disconnect the warning signals once production becomes the #1 priority.

Level 3 - SPC, with Corrective Action = Inspection. Short term containment equals auditing or 100% inspection.

Level 4 - SPC, with Corrective Action = Equipment Flag. Process is stopped or equipment automatically shuts down, so that defects will not move forward.

Level 5 - SPC, with Corrective Action = Countermeasure. Improvements are made so that defect cannot occur again.

Where are you ? Are at the best (level 5) or the worst (level 1).

1.2 SPC - should apply on procuss inputs instead of outputs

Most companies apply SPC to finished goods (Y’s) rather than process characteristics (X’s).

The full power of SPC methods to improve quality, increase productivity, and reduce cost can only be realized if the process inputs become the focus of our effort.

Tony Lim 23-Aug-2007

Monday, August 20, 2007

Part II - Response Optimization

Thursday, August 16, 2007

DOE - How to optimize the setting for two parameters? Part I

Case Study

•Mr John wants to determine the optimum setting for the wire diameter and winding tension.

•His goal is to achieve the target values of the two main responses, coil resistance and coil mass.

•Given spec are

–coil resistance, max spec is 5.985 ohm ,min spec is 5.415 ohm and target value is 5.80 ohm

–Coil mass, max spec is 0.4692 g , min spec is 0.4508 g and target value is 0.4650 g

•Mr John wants to determine the optimum setting for the wire diameter and winding tension.

•His goal is to achieve the target values of the two main responses, coil resistance and coil mass.

•Given spec are

–coil resistance, max spec is 5.985 ohm ,min spec is 5.415 ohm and target value is 5.80 ohm

–Coil mass, max spec is 0.4692 g , min spec is 0.4508 g and target value is 0.4650 g

How to optimize the setting for both inputs (wire diamtere and winding tension) in order to achieve the target values of responses?

Guideline (using Minitab):

•Stat>DOE>Factorial>Create Factorial Design

–2 factors, 2 levels

–Enter the data for both responses (Coil res & Coil mass)

•Stat>DOE>Factorial>Analyze Factorial Design

•Stat>DOE>Factorial>Response Optimizer

–Click Setup.

–Goal for both responses should be “target”.

•Stat>DOE>Factorial>Create Factorial Design

–2 factors, 2 levels

–Enter the data for both responses (Coil res & Coil mass)

•Stat>DOE>Factorial>Analyze Factorial Design

•Stat>DOE>Factorial>Response Optimizer

–Click Setup.

–Goal for both responses should be “target”.

Tony Lim 17-Aug-2007 1pm

Tuesday, August 14, 2007

Monday, August 13, 2007

How to optimize your sales ?

.jpg)

1. Increase the number of customers

2. Increase the value of sales.

3. Increase the frequency of sales.

If you can improve all the above 3 items by 10%, then the sales turnover will be increase by at least 30%.

For example, if your existing sales data are:

No of customer = 20

Value of sales (average) =$1000

Frequency of sales = 10

Your existing sales turnover

= No of customer *Value of sales*Frequency

= 20*1000*10

=$200,000.

If you can improve all the three items by 10%:

Your sales turnover will be

=21*1100*11

=$266,200. (30% increase)

Tony Lim 14-August-2007

Sunday, August 12, 2007

Type of Waste:

Type of waste:

1)Overproduction

-Producing more than is needed before it is needed

2)Inventory

- Maintaining excess inventory of raw materials, parts in process, or finished goods

3)Transportation

-Wasted effort to transport materials, parts, or finished goods into or out of storage

4)Motion

- Any wasted motion to pick up parts or stack parts

- Also wasted walking

5)Over-processing

- Doing more work than is necessary

6)Correction

- Repair or Rework

7)Not fully utilize human resources

- Not using operators to their maximum ability

8)Loss Opportunities

- Failed to launch product on time / capture the market share

- Loss the sales

Tony Lim 13-Aug-2007 Malaysia

1)Overproduction

-Producing more than is needed before it is needed

2)Inventory

- Maintaining excess inventory of raw materials, parts in process, or finished goods

3)Transportation

-Wasted effort to transport materials, parts, or finished goods into or out of storage

4)Motion

- Any wasted motion to pick up parts or stack parts

- Also wasted walking

5)Over-processing

- Doing more work than is necessary

6)Correction

- Repair or Rework

7)Not fully utilize human resources

- Not using operators to their maximum ability

8)Loss Opportunities

- Failed to launch product on time / capture the market share

- Loss the sales

Tony Lim 13-Aug-2007 Malaysia

Thursday, August 9, 2007

Why we need Lean Manufacturing?

Why we need Lean Manufacturing?

-Stronger competitive environment

-Due to price erosion, all manufacturing industries face continuous pressure to reduce price and to remain competitiveness in the market

-Need to lower the operational costs in order to sustain the profit margin

-In an effort to become more profitable many companies are turning to lean manufacturing.

What is Lean Manufacturing?

•Lean is a manufacturing philosophy that recognizes WASTE as the primary driver of cycle time, and employs techniques to continually drive out the waste in processes

•Lean is reducing the time from customer order to manufacturing and delivering products by focuses on eliminating non value added activities in the production stream

•Lean production is not about eliminating people

•Lean is a manufacturing philosophy that recognizes WASTE as the primary driver of cycle time, and employs techniques to continually drive out the waste in processes

•Lean is reducing the time from customer order to manufacturing and delivering products by focuses on eliminating non value added activities in the production stream

•Lean production is not about eliminating people

Lean is about doing more with less resources:

–Less time

–Less inventory

–Less space

–Less money.

Lean is about speed and getting it right the first time.

What is waste?

•VALUE: Any activity that changes the shape of a product to meet customer needs

•WASTE: Activities that consume time, resources and space, but does not change the form of the product OR “Anything that adds Cost to the product without adding Value”

According to Fujio Cho, Toyota, Waste - “anything other than the minimum amount of equipment, materials, parts, space, and worker’s time, which are absolutely essential to add value to the product.”

•How to determine a non-value added activity? A good test is “would my customer be willing to pay for this activity?”

•VALUE: Any activity that changes the shape of a product to meet customer needs

•WASTE: Activities that consume time, resources and space, but does not change the form of the product OR “Anything that adds Cost to the product without adding Value”

According to Fujio Cho, Toyota, Waste - “anything other than the minimum amount of equipment, materials, parts, space, and worker’s time, which are absolutely essential to add value to the product.”

•How to determine a non-value added activity? A good test is “would my customer be willing to pay for this activity?”

Tony Lim 10-Aug-2007 Malaysia

Wednesday, August 8, 2007

How to improve your process capability?

Capability analysis study is a set of calculations used to assess whether a system is statistically able to meet a set of specifications or requirements.

The objective of a capability analysis is to understand how the process is performing relative to the desire goals

•How is the process performing today?

•How much does it need to improve to reach the goals?

Example - product performance compared to customer specifications.

How to improve your process capability?

Steps :

Step 1. Gather data on your existing parts.

Step 2. Analyse the data.

Step 3. Formulate the improvement plan based on findings from step 2.

Paired t test

Case Study - to detect the changes of diameter

Method: use paired t test to analyse the size of Diameter(After Turning, Hardened, Tumbling & Passivation)Step 1: Data collection

Process Flow are :

Turning => measure the diameter =>Hardening=>measure the diameter=>Tumbling=>measure the diamter=>Passivation=>measure the diameter.

All samples are labelled.

Step 2: Data Analysis (Paired t test)

Subscribe to:

Comments (Atom)

.jpg)